Online Technical Training Blog

What’s the Difference between the PLC and PLC Technician II Certificate Programs?

Probably the most common question that we get from potential PLC students is “what’s the difference between our PLC and PLC Technician II Certificate programs?”

The answer is a bit technical but we’ll try to keep it short and simple.

Both programs provide a thorough review of PLCs but with one very important difference. The difference is defined by which generation of PLC technology is covered in the program and emulated, in the accompanying simulation tool. The PLC Technician Certificate covers the older more established PLC technology which uses traditional Input/Output (I/O) based addressing versus the PLC Technician II Certificate, which covers the newer, more advanced PLC technology, that uses tag-based addressing.

Both are widely used in industry today, so to really master PLCs in manufacturing you should work towards a basic understanding of both. For someone entering or working in the industry, being versatile and multifaceted with a working knowledge of both types of technology can be a great asset. Having well trained workers who can move comfortably between these levels can be critically important from the perspective of a hiring manager or supervisor.

So that’s the difference.

Now, here’s a bit more information to help you decide which program might best fit your training needs.

The PLC Technician Certificate Program

The PLC Technician program curriculum incorporates traditional I/O based addressing which targets the Allen Bradly SLC 500 and RSLogix 500 hardware and software system. Over the years, this older generation of PLC hardware/software has been adopted by a wide base of companies across a wide range of industries and manufacturing applications. This program incorporates traditional I/O addressing, providing highly targeted introductory training which is most appropriate if PLCs are new to you or if your company is using this older generation of PLC technology. The program includes PLCLogix 500, the interactive PLC simulator that emulates the Rockwell (Allen-Bradley) RSLogix 500 series PLC control software.

The PLC Technician II Certificate Program

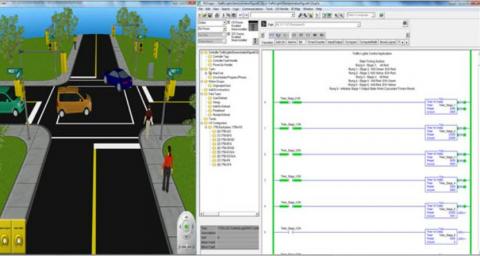

The PLC Technician II Certificate also introduces PLC theory but covers more advanced programming content and applications, including DCS & SCADA systems . It includes PLCLogix 5000, an advanced PLC simulator that emulates the Rockwell Logix 5000 series PLC control software. The RSLogix 5000 system uses more advanced tag-based addressing. This second generation programming environment is gradually replacing older systems due to its flexibility, power and unique capabilities. If you have some experience troubleshooting PLCs or if you know your company is using this generation of technology, this program is probably for you.

The PLCLogix 5000 simulator, as seen in the example above, provides the simulated environment in which students learn about and experiment with tag-based addressing. It incorporates ten interactive simulations called 3DWorlds where interactive labs are conducted. The 3DWorlds include a Batch Mixer, Stationary and Moving Car Wash, Single and Dual Air Compressors, Silo/Hopper, Warehouse Doors, Elevator, Bottle Line and Traffic Lights. These 3DWorlds are controlled by ladder logic programs that allow you to create, run and observe the operation of complex control devices and systems in real time, providing a "hands on" learning and lab experience.

There is material that is common between the two programs, so if you do decide to eventually take both, you are given full credit in the second program for any overlapping material covered in the first.

If you are still deciding which program is better suited for you, complete our quiz to determine which PLC program is right for you!

To find out more details about these programs, or to help you more fully understand which program might be best suited to you, please give us a toll-free call and speak to one of our a program advisors.