Online Technical Training Blog

Safely Return to Work in Manufacturing During COVID-19

As Covid-19 is brought under control, many people are anxious to get back to work. While some may be able to work from home, it is important that safety measures are in place for those who must physically return to their workplaces. The manufacturing industry must have measures in place to prevent the potential spread of the virus as technicians return to warehouses, factories, and other workplaces. Let us review a few new technologies and procedural changes employers can implement to ensure that their spaces are safe for returning technicians and visitors.

Introducing New Safety Technologies

While the pandemic has caused slowdowns in many areas, it has in fact sped up the development and introduction of new technologies, especially in the area of sanitation and safety procedures. By implementing some of these technologies, employers will be better prepared to keep their employees safe despite their return to work.

1. Face Detection Software

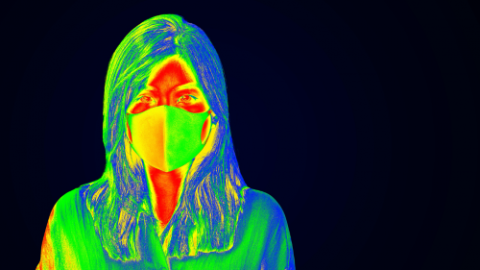

Many scientists are working on reimagining safe workplace technologies, or repurposing existing technologies to suit the purposes of Covid-19 prevention. One technology that could assist in ensuring worker safety, is facial recognition software. Not only would this technology provide added security when workers enter the workplace in the form of face detection, but it can also screen for visible symptoms and take workers’ temperatures. Those exhibiting symptoms can be detected before they ever enter the workplace, and sent home to self-isolate.

Further, this software can be used within the workplace itself, monitoring on-the-job behaviours. It could be used to provide contactless authentication, enforce social distancing, and detect whether workers are wearing face masks properly at their work stations. If someone pulls their mask down past their nose, for example, the AI will detect it and send an alert. This can help curb the spread between employees who might need to work in closer quarters, or who come into contact with each other more regularly.

2. Advanced Robot Interactions

Often, close contact between workers can be difficult to limit. However, new robotic technology will allow workers to interact with robots more closely, without increasing the danger to themselves. Use of cameras and other sensors in robots mean that they can better sense human presence, thus becoming safer for close interaction. These robots could be used to prevent direct contact between employees, as they may be able to act as intermediaries, complete more complex tasks, or assist in tasks that may usually take multiple employees to complete.

3. Sanitation Procedure

Since the beginning of Covid-19, major developments have been made in the area of contactless sanitation. There are numerous robotics on the market, many using UVD rays to sanitize surfaces and spaces. They are being used in hospitals to grocery stores, and can sanitize surfaces much more quickly and thoroughly than a traditional cleaning crew—and with less human contact. Use of one of these robots to sanitize work-places during off hours could help prevent potential spread, especially in workplaces where materials and tools are handled regularly.

Changing Daily Procedures

While adopting new technology would be ideal for most businesses, not all employers will be able to implement such updates prior to workers returning. Budget restraints, installation timeline, and technology availability could all affect employers’ ability to implement technological screening and sanitization advancements. There are, however, a number of changes that can be made to day-to-day procedures to ensure minimum potential contact and spread of the virus.

1. Manual & Mandatory Symptom Screening

The first precaution that can be taken when allowing employees back to work is implementing a mandatory symptom screening procedure. As employees arrive back to work, they are suggested to divulge any potential risks they have recently come into contact with—have they travelled out of the country, for example, or have they been in contact with anyone who has shown symptoms. Invest in a thermometer for quick temperature screenings, and send anyone home who does not pass these tests. Continue these measures on a daily basis, or continue periodically in a “random testing” format. It is important employers do all they can to prevent workers from bringing the virus into the work place.

2. Adjust Visitor Hours and Access

Contact between workers and visitors to the workplace should be minimized in order to keep workers as safe as possible. Necessary meetings with vendors, maintenance workers, or even corporate visitors should be scheduled during off-hours, where possible, so that employees are not present. This will minimize the chance of accidental exposure as employees are less likely to come into contact with outsiders as they go about their daily tasks. When it is impossible to schedule visitors during non-business hours—deliveries, for example—management should designate certain representatives to meet with them. This will minimize their contact with multiple employees, keeping potential spread to a minimum. A record should be kept of all visitors, to allow for contact tracking if necessary.

3. Scheduling for Minimal Contact

Not only should contact between employees and visitors be limited, but so too should contact between individual employees. Where possible, worker hours should be adjusted so that contact is minimized. Start and end times could be adjusted to stagger when employees are arriving and departing from work. Similarly, multiple break times and lunch times should be scheduled, to prevent large gatherings within the facility as workers take their breaks. This may be difficult to coordinate, but it could make the difference in keeping employees safe while they are at work.

Together with scheduling employees to come into limited contact with each other, employers should also work towards minimizing contact in other facets of the business. Setting up contactless drop-off points for deliveries, for example, would limit potential contamination between delivery workers and employees. While such measures may seem like unnecessary precautions, all of these steps will work together not only to minimize the risk of employees catching Covid-19, but also to prevent its spread throughout their workplace.

How to Decide Which Changes should be Made?

What changes should be made to a workplace to ensure safety, and to what levels of precautions will one go? The answer to these questions will differ across workplaces, and will depend on a number of factors. Employers should do a risk assessment, and balance the risk of re-opening workplaces against the potential gains, and potential losses, that could be associated with reopening. Some questions employers should ask themselves are:

- Is it worth re-opening now, or would it be more beneficial in the long run to work up more slowly to a future opening? Would losses from a second shut-down due to contamination outweigh the gains from reopening?

- Is there budget available to invest in new technologies such as facial recognition, updated robot tech, or additional security? Is there the budget to make the changes necessary for basic social distancing?

- How often do employees come in contact with each other? Are workstations close together, or is there separation while they complete their work? Is it possible to minimize contact between them on a daily basis?

No matter the answers to these questions, it is important that employers follow their local guidelines and health protocols set out by the government. Constant reassessment of risk factors and precautions taken will also be beneficial in allowing workplaces to open, and continue their operations safely.

Taking the proper precautions is of the utmost important in the return to workplaces during and post-pandemic. Whether you are an employer or employee, it is important to always assess your risks, and follow proper procedures when making such important decisions. Returning to work safely is of the utmost importance not only to the economy, but for the workers who allow it to run, and a safe, cautious reopening will lower the potential of future shutdowns.