Online Technical Training Blog

Learning to program PLCs with GBCtechtraining

One of the most commom questions asked by our prospective students is “Learning all about the theory and application of PLCs is great but will I be able to program PLCs after taking the PLC Technician Certificate program?” The answer is yes. The knowledge you will acquire from the program will provide you with the programming skills needed to maintain, troubleshoot or edit existing PLC control applications. These skills will assist you in general everyday maintenance tasks, as well as when you need to adapt to changes in your process such as equipment malfunctions, product line changes, or plant upgrades.

Of course we must begin at the beginning

We all had to walk before we could run and for that reason the program begins with the basics. Having a solid understanding of the basic concepts associated with PLCs in general is an essential part of being successful while learning to program. To that end, the architecture and constituent components of a PLC system as well as the Scan Cycle and how a PLC goes about interpreting and executing a given program are covered prior to the introduction of programming. The student is also provided with details regarding common types of physical I/O modules (ie. Discrete, BCD, or Analog) and the field devices most commonly employed in modern day control systems. The addressing scheme, memory allocation, and file system used with the specific series of controller are also illustrated. Lastly, to finish out the introductory sections of the program, the topics of general PLC installation and maintenance are explored. Once the student has a grasp of these core concepts, they will have the requisite knowledge to learn to begin to program PLCs for use in process control applications.

Now we are ready to start programming

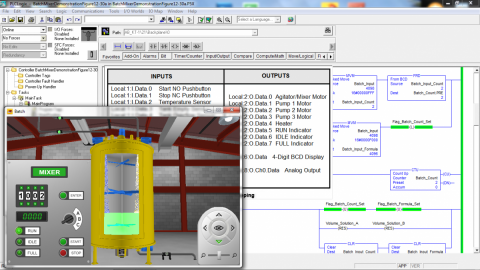

The powerful PLCLogix simulation tool is integrated with the programs learning materials, providing the student with a virtual environment in which to build their PLC programming skills. With each new programming instruction introduced in the program theory, an example of its utility and application is demonstrated by way of accompanying lab project files for simulation. The simulation tool comes with a ladder logic editor for programming, as well as 10 virtual 3D environments, emulating real world control applications that the student can interact with and manipulate using programs they create or modify in the ladder logic editor. Each 3D environment provides the student with a variety of real world input and output field devices. In addition to the lab project files, at the end of each section that deals with programming, several practical programming examples are provided which utilize the 3D virtual control environments. In these Practical Example sections, the student is tasked with adding functionality to existing PLC applications using their newly acquired programming knowledge. In addition to the Ladder Logic programming techniques used throughout the course materials, an introduction to alternative programming formats such as Structured Text (ST), Function Block Diagrams (FBD), Instruction Lists (IL), and Sequential Function Charts (SFC) is also provided. These alternative programming techniques are discussed generally, providing the student with a basic understanding of how these advanced programming languages are interpreted and used.

What does the availability of a virtual lab mean for the student

PLCLogix allows the student to gain real world programming experience in a safe and controlled environment. Using this simulation tool, the student is able to run through multiple iterations of “what if” scenarios that arise when learning to work with modern control applications. It supplies them with the opportunity to explore the functionality and implementation of all the programming instructions presented in the program without running the risk of injury or damage to expensive industrial control equipment. A “Step” mode is available in the simulation tool that allows the student to execute their control program one scan cycle at a time. This feature can be extremely helpful when learning the distinct behavior of each of the instructions provided in the instruction set, as well as when following the flow of program execution.

Each 3D virtual environment comes with an I/O mapping table allowing the student to control the virtual environment using ladder logic programming techniques introduced and explained throughout the program materials. The availability of these virtual environments allows the student to develop, edit, and debug their own application specific programs as they learn the controller’s instruction set, all the while receiving vital visual feedback for any modifications or edits made to their programs. While their program is running, the student can navigate around inside the virtual environment using the multiple camera angles provided in the simulation tool, allowing them to zero in on the areas affected by program edits/modifications and view the resulting changes in the application’s behavior. This visual feedback serves to reinforce the associations between a student’s program, and how that program will behave in real world applications. This type of visual reinforcement has been demonstrated to be a great asset to students when learning new concepts in the absence of real world equipment.

We know that practice makes perfect

Having the PLCLogix simulation tool allows students to practice as much as they want. They can hone their programming skills while working their way through the program and will continue to benefit from the tool well after course completion. PLCLogix has the same look and feel as the industry standard RSLogix software used for programming real PLCs. This means that the procedures and skills acquired through the course materials and use of the simulation tool are easily transportable to the real world tools most commonly used in the industry today. After mastering the PLC basics and the core instruction set used for programming, the course goes on to cover Number Systems, Binary Math and Boolean Theorems, and basic Networking concepts, providing useful insight that helps round out the students understanding of PLC programming concepts. The ability to employ these concepts using the simulation tool greatly assists the student in their efforts to expand and enhance their recently acquired PLC programming knowledge.

So to answer the question

Upon completion of the program students leave with a sound working knowledge of PLC programming and will be capable of performing the majority of maintenance, editing, or debugging tasks associated with ladder logic PLC programs. The program’s theory is delivered in an organized and logical manner. The interactive materials and simulation tool are provided to reinforce concepts learned in the theory that is being delivered. The ability to practice hands-on programming presented in an industry standard format, and have the skills acquired be portable to real world equipment, is an essential component of these PLC Technician Certificate training programs.

To find out more about our online PLC programs call us toll-free at 1-888-553-5333 and speak to one of our Program Consultants.