Online Technical Training Blog

Composite Materials Drive Next Generation Manufacturing

Composite materials are the manufacturing approach of the future, at least according to current thinking. Highly engineered carbon composites are the basis for a whole new generation of advanced materials that are useful in both the aerospace and the emerging commercial space industry – and, in future, the automotive industry as well. Also, advances in technology have allowed companies to more easily predict the performance of a finished composite structure after performing process simulations.

For example, the company AEC has made great strides in its manufacturing process. According to Brian Coffenberry, its senior VP of business development, AEC has developed a “fairly sophisticated capability” to use simulated data to calibrate the structural performance of its materials.

Case Study: AEC

Originally a textile weaving company, AEC took the leap to composite materials when its parent company Albany International purchased Techniweave Inc. in 1998. At the time, Techniweave produced fabrics using technical fibres such as carbon and ceramics—and its development programs were focused on making complex, 3D moulds for composite structures.

Following this, the company acquired two other companies with roots in composite and fibre technologies to become AEC, and in partnership with engine manufacturer Safran, planned to use their expertise to develop advanced composites for landing gear and aircraft engines. AEC’s background in weaving makes it an ideal candidate to fully explore the possibilities of composite materials.

Composites in Space

One application of composites is in the commercial space industry, which is poised for a boom in the next few years. Since private companies such as Elon Musk’s SpaceX have renewed interest in commercial space travel and applications, interest in composite materials—and specifically their high strength- and stiffness-to-weight ratio—has also grown. A huge amount of companies now use composites to fit their space-going vehicles. For example, Orbital ATK produced the world’s first privately-developed launch vehicle over 25 years ago, and its Cygnus service module contains carbon composite skins on its aft deck structure, as well as carbon composite sandwich structures in its rigid solar arrays. Many other spacecraft use these materials in the construction of various different components.

How to Make Composite Materials

These days, 3D printing is all the rage—and that’s exactly how composite materials are made. Known in the industry as additive manufacturing, the technique allows three-dimensional geometries of almost any solid shape to be ‘printed’ from a digital model of the solid. Initially developed for prototyping objects (and therefore allowing designers a way to develop prototypes without having to make moulds), the process is now at a point where not just prototypes but entire finished products are being created using additive manufacturing.

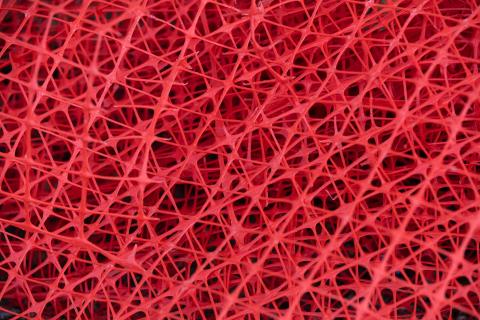

Essentially, the process involves a continuous deposition of material built up in layers of fibres that intermingle and reinforce one another in the shape that the manufacturer wants. It’s important to note that for anisotropic materials (i.e., those that are not the same all the way through), the deposition process is not fully understood, and they can deform while printing from the desired shape. That means that simulations that model additive manufacturing, especially using fibre-reinforced materials, have to take this shape change into account. It’s a tricky problem, but it’s necessary to make sure that the desired geometry is achieved.

Next-Gen Manufacturing

Currently, manufacturing techniques are centered around solving the digital design problems that come with understanding the physics of composites and how they react during deposition. The takeaway from all this is that unlike many conventional materials, composites are manufactured using highly complex, precise procedures that require highly trained and educated technicians to work on them. Soon, factory automation will require qualified Electronics and Robotics Technicians, as well as PLC programmers, to ensure that the factory is running smoothly.

This need for skilled and educated workers with knowledge of these fields will have to be filled in part by the retraining of adult workers, something that online technology courses are particularly well suited for. George Brown College provides such programs, and awards a certificate of completion following the end of the program. For anyone who is interested in a career change into composite manufacturing, such courses are a crucial way to expand their experience and knowledge to succeed in this highly competitive field.