Online Technical Training Blog

Discover PLC Applications in Everyday Life: How PLCs Control Everyday Systems

Programmable Logic Controllers , also known as PLCs, are robust industrial electronic systems used for controlling a wide variety of mechanical systems and applications.

So how common are PLCs why are they so important?

Well, in our heavily technologically reliant society, PLC systems are found everywhere, including in our factories, office buildings and even controlling the traffic on our streets. PLCs are at the very heart of the control of many critical technologies that most of us don`t give even a second thought to, they are so seamlessly and invisibly integrated into our daily lives.

Here are some examples of everyday mechanical systems that are controlled by PLCs:

1) Road Traffic Signals

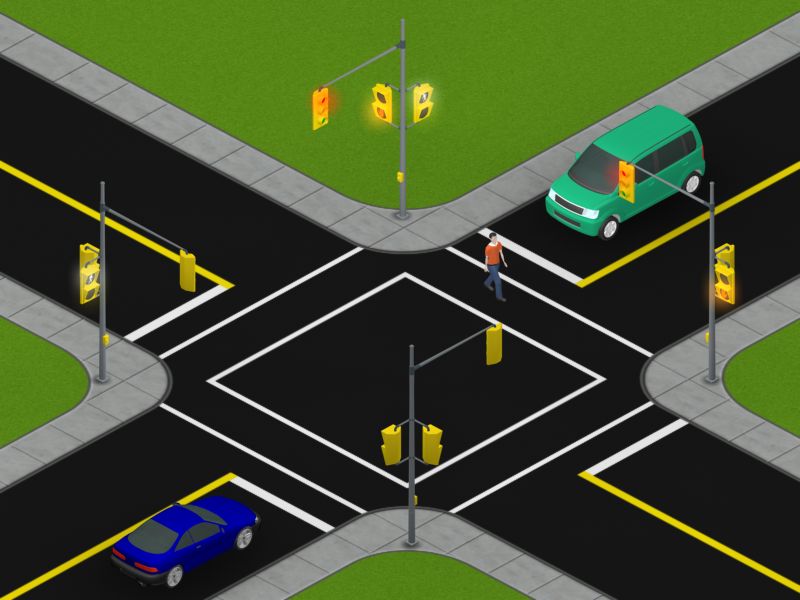

It’s difficult to picture our modern world without traffic signals. Those three colored streetlights are used and understood by people all around the world. This simple but ingenious application of the PLC has a long history in major cities and small towns all around the world, since their first application traffic control in 1926 in London, England. These traffic lights, that we take for granted every day are monitored and controlled by PLC hardware and software, running dependably and without fuss 24/7/365 days a year.

Have you ever noticed when you travel at rush hours on a busy street, it is an entirely different experience than at low traffic periods? If a pedestrian pressd the button to cross at an intersection, how does that affect flow of the vehicles? Do traffic lights actually “see” an emergency vehicle and allow it to blaze through an intersection? Using emergency vehicle transponders, sensors, and plc circuits to control the traffic lights, traffic flow is coordinated and managed to allow for more timely and direct rescue services.

2) The Automatic Car Wash

In any busy metropolis where car traffic is present, there are many gas stations accompanied by automatic or “touch-less” car wash stations. As you take a trip inside the touch-free carwash, you will find the water mixed with cleaning solutions, blasting the surface of the vehicle and spinning wipers for scrubbing. Every process is calculated and carefully controlled, from how many litres/gallons of soap is used, to the length of time those tall rotating wipers spin. These time and work saving services are completely automated by PLCs, with little human interaction other than a press of button at the entrance.

Watch this video to learn how to work with I/O forces in an automatic car wash!

3) The Elevator

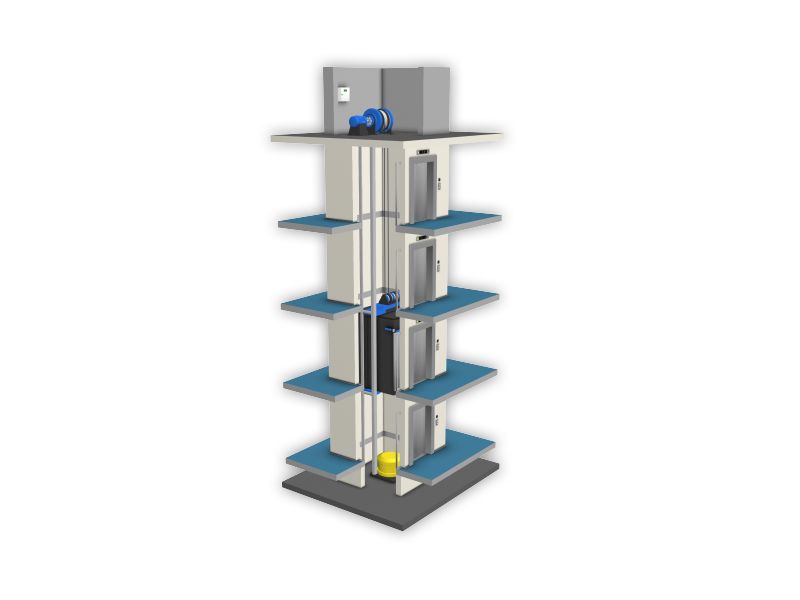

The elevator industry is on the rise; pun intended. In every multifloor building, an elevator is present, no matter how short or tall. Recall those times when the elevator door opens and you step inside to find that it was headed in the wrong direction? Has this ever made you wonder who or what is controlling it to do so? To give you a clue, there is a defined program running in a PLC that detects the different floors requesting the elevator and directing the elevators in their required direction. These programs are sets of ladder logic instructions that are loaded into the PLC controlling the lift. The controllers are usually not located in the elevator itself but at a specific location on the roof of the building or in a nearby control room. I once naively believed that summoning an elevator to my floor was performed on a first come, first serve basis but this is not the case, if the elevator is already in motion. Most elevators are programmed and controlled by PLCs to take the most optimized route through any pending button calls and make their directional decisions based on that.

4) Automatic Doors

Do you recall a time not too long ago when a person might be hit by an automatic door swinging open? Luckily today, there are better PLC controls with better built-in sensor on both sides of the door to prevent such occurrences. There are a many ways for an automatic door to function but in general they operate by way of a detector, for example a beam of light being broken, causing the system to identify something in front of, or between, the doors.

5) Conveyer Belts

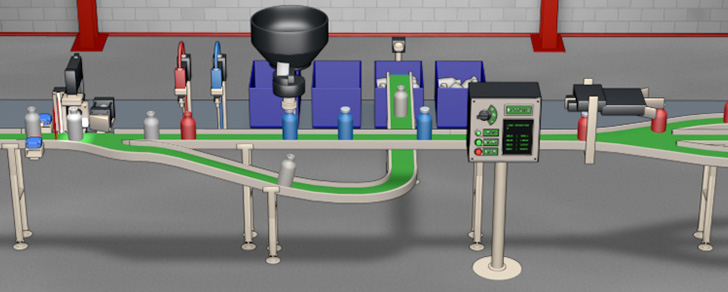

When paying for your purchases at your neighborhood supermarket, the lowly conveyer belt moves your purchases into the reach of a friendly cashier. Imagine the inconvenience, if a plc was not there helping control the belt, making the process of checking out simple and painless. Bigger conveyer belts can be found in airports where they transport people or put your luggage on carousel until you claim it. There are even giant conveyor belts that transfer construction materials. Conveyor belts are also used in most manufacturing plants due to their convenience and uniform motion.

6) Roller Coasters

Many people love exploring new heights and pushing themselves towards the thrill of a near death experience, on you guessed it, the PLC controlled roller coaster. Whether or not you scream at the top of your lungs is a different story.

Typically, the PLC control in roller coasters is for bringing it upwards before the big drop. It is also used for safety measures so that the cars do not reverse in direction. Imagine travelling backwards on the huge dip; it wouldn’t be as thrilling as the gravitational force pulling down.

Almost everywhere you look today, PLCs are playing an important part controlling the technology that supports our hi-tech lifestyles. From traffic lights to roller coasters they provide us with robust and reliable control mechanisms that improve our lives. PLC technicians work to maintain and support these technologies, providing a critical service that keeps us safe and moving through our busy lives.

Let us know your favorite, most unappreciated application of the plc that others might be surprised to find out about in our comments section below!